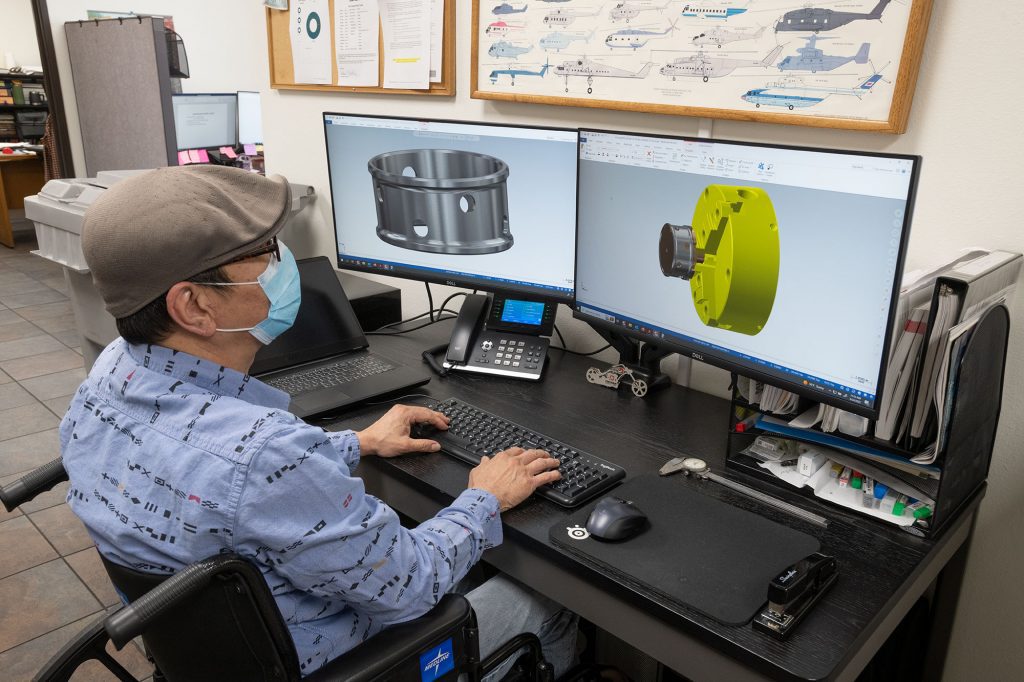

OUR CAPABILITIES

PROGRAMMING

At Duncan Industries we strive to produce parts to our customers’ requirements. We specialize in producing parts from hardened materials to achieve exacting tolerances. Our engineering know-how is built into each part. We start by modeling and programming each job to assure the final results will achieve an acceptable first article.

GRINDING

Our manufacturing foundation of machining and precision grinding allows us to zero in on the closest tolerances and finishes.

MILLING

3 and 4 axis milling machines compliment our production turning capabilities producing slots, holes, tapping, cross holes, key-ways, and an endless number of geometry types while holding feature control tolerances.

TURNING

Turning capabilities are our strong suit, bar feeders and chuckers have up to 8” turning diameters. We produce blanks for heat treat and finish parts to four decimal place accuracy. Combine this production with our grinding and lapping capabilities, we achieve finishes down to 2 micro-inches and .000050” cylindricity.

FINISHING AND MARKING

We employ a team of skilled crafts persons who polish, deburr, identify, mark, and package to our customer specifications. Automated dot peen machines are capable of serialization.

COATINGS AND ASSEMBLY

Duncan has special process capabilities to apply fluidized powder coating utilizing blasting, pre-heat in our furnace, and turning to size. We assemble utilizing adhesives, pressfits, and thermal fits.

NON-DESTRUCTIVE TESTING

Duncan also qualifies to perform special process inspections which compliment our manufacturing capabilities. Using the nital etch process we are able to evaluate our grinding processes real time for wheel break down and dressing. We also perform magnetic particle inspections to evaluate parts for hidden cracks or surface defects.

QUALITY ASSURANCE

We determine process control utilizing many different types of inspection test equipment. We have mechanical capabilities to within .00001” accuracy, programmable CMM & articulating arm CMM, hardness testing, and air gaging. Our capabilities and inspection talent give us the ability to assure we meet every characteristic and feature of the engineering drawing.

STORAGE

Duncan is able to store our parts inventory utilizing conveyor type automation. Our stock is counted and organized for easy access to ship when customer need arises.

Equipment List

View our latest equipment list